Why Chinese Weights are Unmatched in Durability

In the world of weightlifting, the reliability and longevity of weights are paramount. While numerous options exist, Chinese weights have earned a reputation for unparalleled durability. This comprehensive guide explores the history, craftsmanship, materials, and cultural influences that contribute to the enduring quality of these weights. By understanding these factors, athletes and gym owners can make informed decisions to maximize their investment and workout experiences.

The Significance of Chinese Weights in Modern Fitness

Throughout history, Chinese weights have significantly impacted weightlifting. Their durability and precision make them a popular choice for athletes worldwide. Used extensively in gyms, training facilities, and international competitions, Chinese weights are recognized as a benchmark in weightlifting equipment.

A Legacy of Craftsmanship: History and Tradition

The history of Chinese weightmaking is intertwined with the country's rich cultural heritage. Traditional Chinese weights were often crafted from cast iron, a material valued for its strength. Over centuries, artisans refined their techniques, developing meticulous processes to ensure accuracy and longevity. This tradition has been passed down through generations, upholding principles of excellence.

Craftsmanship and Attention to Detail: The Cornerstones of Quality

Chinese weights are meticulously crafted, blending traditional techniques with modern advancements. The process involves precision casting, grinding, and rigorous inspection. This commitment to detail results in smooth surfaces, precise dimensions, and unwavering balance, guaranteeing weights that withstand intense training sessions.

The Art of Casting: Shaping Durability

The casting process is critical to the durability of Chinese weights. Skilled artisans employ advanced casting techniques, using high-quality iron alloys to enhance strength and longevity. Molten iron is carefully poured into meticulously designed molds, ensuring precision in shape and consistency in density. This meticulous process provides the characteristic strength and durability that Chinese weights are known for.

Grinding and Finishing: Achieving Perfection

Once cast, Chinese weights undergo a grinding and finishing process to remove imperfections and excess material, resulting in smooth surfaces and precise dimensions. Final inspections ensure each weight meets stringent quality standards, guaranteeing the precision and reliability essential for optimal performance.

Materials and Alloys: The Science Behind Longevity

The longevity of Chinese weights is due to the exceptional materials and alloys used in their construction. Cast iron, the primary material, is known for its strength and resistance to wear. Advanced alloys, incorporating elements like carbon, manganese, and chromium, further enhance durability and performance.

Exploring Alloy Compositions: Tailoring Performance

The composition of alloys varies based on the weight type and intended use. General-purpose weights use alloys with high iron content, balancing strength and affordability. Competition-grade weights incorporate specialized alloys to enhance hardness, wear resistance, and durability, meeting the rigorous demands of elite weightlifting.

Heat Treatment: Enhancing Material Properties

Heat treatment processes are used to enhance the durability of Chinese weights. Controlled heating and cooling cycles modify the molecular structure, improving strength and hardness. This process optimizes performance, ensuring the weights withstand repeated impacts and heavy loading without compromising integrity or accuracy.

Innovative Technologies and Processes: Pushing the Boundaries

Chinese weight manufacturers continuously adopt innovative technologies and processes, including advanced casting techniques and precision machining. Computer-controlled processes ensure precise dimensions and consistent balance. This blend of technology and traditional craftsmanship results in weights that meet the exacting demands of modern weightlifting.

Advanced Casting Techniques: Vacuum and Centrifugal Casting

Vacuum casting removes air pockets and impurities from molten metal, resulting in weights with superior density. Centrifugal casting distributes molten metal evenly, ensuring uniform thickness and enhanced structural integrity. These techniques contribute to the exceptional durability and reliability of Chinese weights.

Precision Machining and Computer Control: Achieving Accuracy

Precision machining and computer-controlled processes enable unparalleled accuracy and consistency. Computer-controlled machines perform precise cuts and grinds, ensuring weights meet exact specifications and are balanced and calibrated to within tight tolerances.

Rigorous Quality Control Measures: Ensuring Excellence

Stringent quality control measures are implemented at every stage of production, from raw materials to final inspection. Weights are meticulously inspected for dimensional accuracy, surface finish, and overall integrity. Weights that don't meet quality standards are rejected, guaranteeing that only the most durable and reliable weights are available.

In-Process Testing and Inspection: Maintaining Standards

Throughout manufacturing, Chinese weights undergo in-process testing and inspection. Skilled technicians conduct regular checks on dimensions, hardness, and appearance. Discrepancies are immediately identified and corrected, maintaining the highest quality standards.

Final Inspection and Certification: Guaranteeing Performance

Before shipping, Chinese weights undergo a final inspection and certification process. Each weight is examined for imperfections. Weights that pass are certified, guaranteeing accuracy, durability, and adherence to industry standards.

Cultural Influences: A Commitment to Excellence

The enduring quality of Chinese weights is deeply connected to the country's cultural values, which emphasize craftsmanship, precision, and attention to detail. This pursuit of excellence drives weightmakers to continuously improve their craft.

The Importance of Precision: Accuracy in Every Lift

Precision is a core value, reflected in the accurate calibration and balance of Chinese weights. This level of precision is crucial for safe weightlifting, preventing imbalances and ensuring accurate measurements.

The Value of Durability: Weights That Last

Durability is highly valued, which is reflected in the robust materials and advanced manufacturing techniques used. The enduring quality of Chinese weights demonstrates a commitment to longevity and reliability.

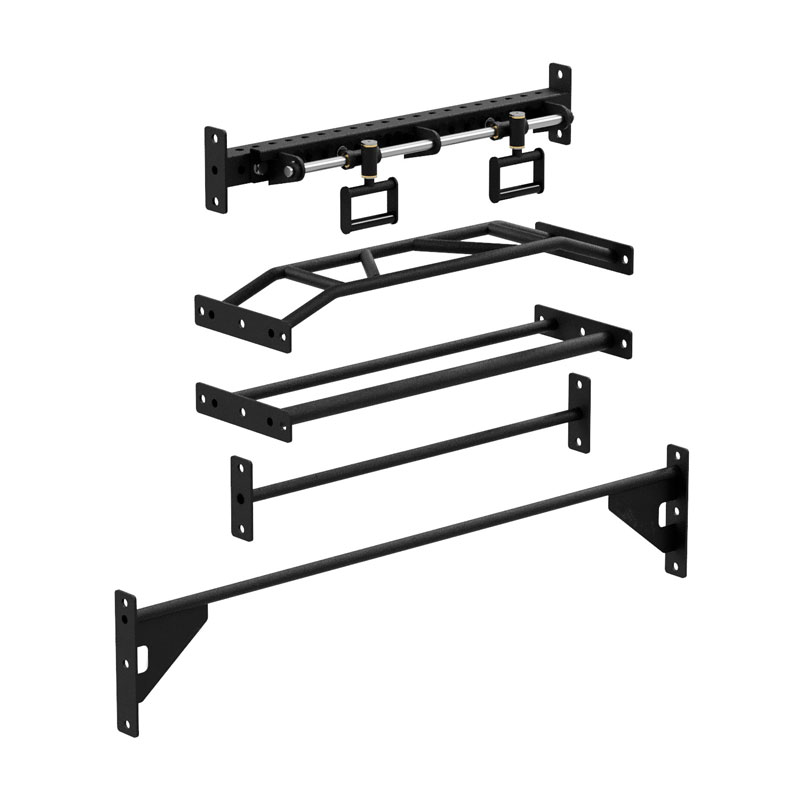

Looking for a Reliable Manufacturing Partner?

If you're searching for a manufacturing partner who emphasizes quality, durability, and customization in weight production, consider exploring suppliers with vertically integrated operations. This approach often translates to better control over quality and more efficient production processes. With decades of experience, vertically integrated factories can support your needs.

Explore customizable weight solutions and learn more about streamlined production[Leadman Fitness].

Conclusion: Investing in Quality and Performance

Chinese weights are renowned for their unmatched durability, a result of meticulous craftsmanship, innovative technologies, and a deep-rooted cultural commitment to excellence. By understanding these factors, you can make informed decisions when selecting weightlifting equipment, ensuring a worthwhile investment in quality and performance.

Whether you are setting up a commercial gym or a home workout space, choosing the right weights is essential. Look for suppliers who prioritize quality, precision, and durability.

FAQ: Answering Your Questions About Chinese Weights

1. What are the primary materials used in Chinese weights?

Cast iron is the primary material, often enhanced with advanced alloys for increased durability and performance.

2. How does the casting process affect the durability of Chinese weights?

Advanced casting techniques, such as vacuum casting and centrifugal casting, eliminate imperfections and ensure uniform density.

3. What quality control measures are in place?

Rigorous quality control measures are implemented throughout the production process, including in-process testing and final inspections.

4. What certifications should I look for?

Look for certifications that indicate adherence to international quality standards.

5. Are Chinese weights suitable for commercial gyms?

Yes, many Chinese weights are designed to withstand the demands of commercial use, offering durability and reliability.