How to Remove Rust from Your Barbell: A Comprehensive Guide

A rusty barbell is a common sight, particularly in home gyms where equipment might not receive the same level of care and attention as in a commercial setting. The damp air, fluctuating temperatures, and occasional spills can all contribute to the formation of rust on your cherished weightlifting apparatus. This isn't just an aesthetic issue; a rusty barbell poses significant safety risks. Rust weakens the metal, potentially leading to fractures or breakage during use, resulting in serious injury. Furthermore, a compromised barbell can affect your workout, making it difficult to maintain proper form and potentially hindering your strength gains.

This blog post will equip you with the knowledge and techniques to effectively remove rust from your barbell, restoring its functionality and safety. We'll explore a range of methods, from simple home remedies to more advanced techniques. However, it's important to set realistic expectations: some rust damage may be too extensive for DIY solutions and might require professional intervention.

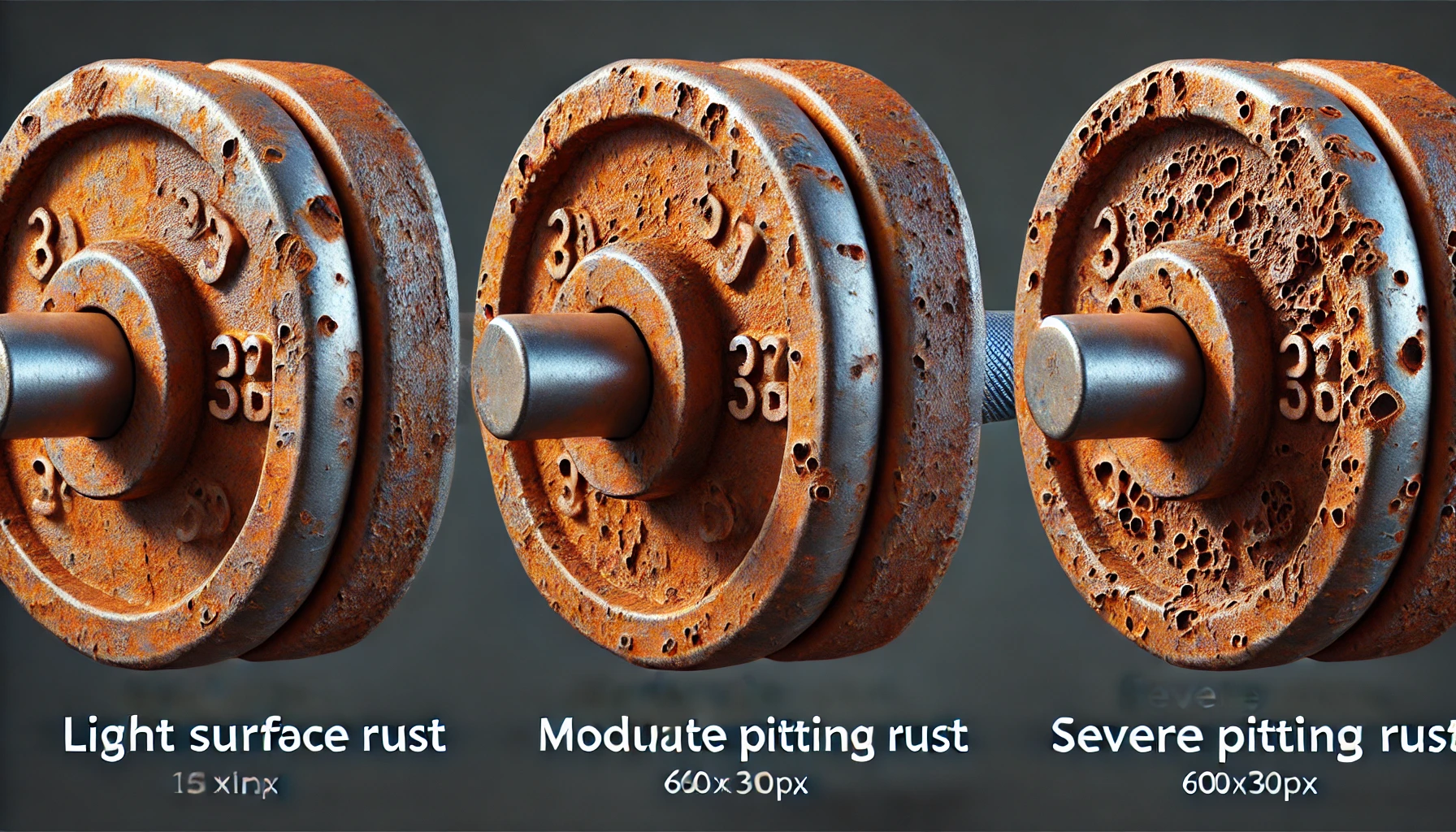

Assessing the Damage: How Much Rust are We Talking About?

Before embarking on any rust removal process, carefully assess the extent of the damage. Two main types of rust are crucial to identify:

Surface Rust: This is characterized by a reddish-brown coating on the barbell's surface. It’s usually relatively easy to remove and doesn't significantly compromise the barbell's structural integrity. Surface rust often appears as a thin layer, easily scraped off with a fingernail.

Pitting Rust: This is more serious. Pitting rust involves the corrosion penetrating deeper into the metal, creating pits and holes. This weakens the barbell considerably and poses a higher risk of failure during use. Pitting rust is often darker and more ingrained in the metal than surface rust.

How Much Rust are We Talking About?

Determining the severity will guide your choice of cleaning method. Light surface rust can often be tackled with simple cleaning techniques. Moderate pitting rust might require more aggressive approaches, while severe pitting often necessitates professional help or barbell replacement.

Safety First: Protective Gear and Workspace

Rust removal involves harsh chemicals and abrasive materials, making safety paramount. Always wear the following:

- Gloves: Protect your hands from chemicals and sharp edges. Choose heavy-duty gloves suitable for the chosen method.

- Eye Protection: Safety glasses or goggles will shield your eyes from flying debris and chemical splashes.

- Respiratory Protection: A dust mask or respirator is crucial, especially when using abrasive tools or chemical removers, to prevent inhalation of harmful particles or fumes.

Establish a well-ventilated workspace, ideally outdoors. If working indoors, ensure adequate ventilation to minimize exposure to fumes. Proper disposal of used materials is also crucial. Follow local regulations for disposing of chemical waste and sharp objects.

Method 1: Simple Cleaning – For Light Surface Rust

For barbells with light surface rust, a simple cleaning might suffice. This involves using a wire brush to physically remove the rust.

Wire Brush Selection: Several types of wire brushes are available. Steel wool is effective but can leave scratches. Brass wire brushes are gentler and less likely to damage the barbell's finish. Choose the brush appropriate for the barbell's material and the severity of the rust.

Cleaning Process: Apply soapy water to the barbell. Using firm but controlled strokes, scrub the rusted areas with the wire brush. A scrubbing pad can augment the cleaning power, especially in crevices. Rinse thoroughly with clean water to remove all traces of soap and rust particles. Finally, dry the barbell completely with a clean cloth.

Method 2: Vinegar Soaking – A Natural Approach

Vinegar's acidity effectively dissolves rust. This method is suitable for moderate surface rust and is environmentally friendly.

Soaking Process: Submerge the rusty barbell in a container large enough to fully immerse it. Fill the container with white vinegar, ensuring the barbell is completely covered. The soaking time depends on the rust severity; light rust might only require a few hours, while heavier rust may need up to 24 hours or even longer.

Enhancing Effectiveness (Optional): Adding salt to the vinegar solution enhances its rust-removing capabilities. The salt acts as an electrolyte, speeding up the chemical reaction.

Post-Soak Cleaning: After soaking, remove the barbell and rinse it thoroughly with water. Use a wire brush or scrubbing pad to remove any remaining loosened rust. Dry thoroughly.

Method 3: Baking Soda Paste – Gentle Abrasion

For delicate areas or lighter rust, a baking soda paste offers a gentler approach.

Paste Preparation: Mix baking soda with water to form a thick paste. Apply the paste to the rusted areas using a cloth or sponge.

Application and Scrubbing: Gently scrub the paste onto the rusted surface using a soft-bristled brush or a non-abrasive cloth. Avoid excessive scrubbing, which could damage the barbell.

Rinsing and Drying: Rinse the barbell thoroughly with water to remove all traces of the paste and dry completely.

Method 4: Commercial Rust Removers – For Stubborn Rust

Commercial rust removers offer stronger solutions for stubborn rust.

Product Selection: A wide array of commercial rust removers is available in gels, liquids, and sprays. Choose a product appropriate for your barbell material and the severity of the rust.

Safety Precautions: Always read and follow the manufacturer's instructions carefully. Wear appropriate protective gear (gloves, eye protection, respirator). Work in a well-ventilated area.

Application: Apply the rust remover according to the manufacturer's instructions. This may involve brushing, spraying, or soaking. Allow sufficient time for the product to work its magic.

Disposal: Dispose of used rust remover according to the manufacturer's instructions and local regulations.

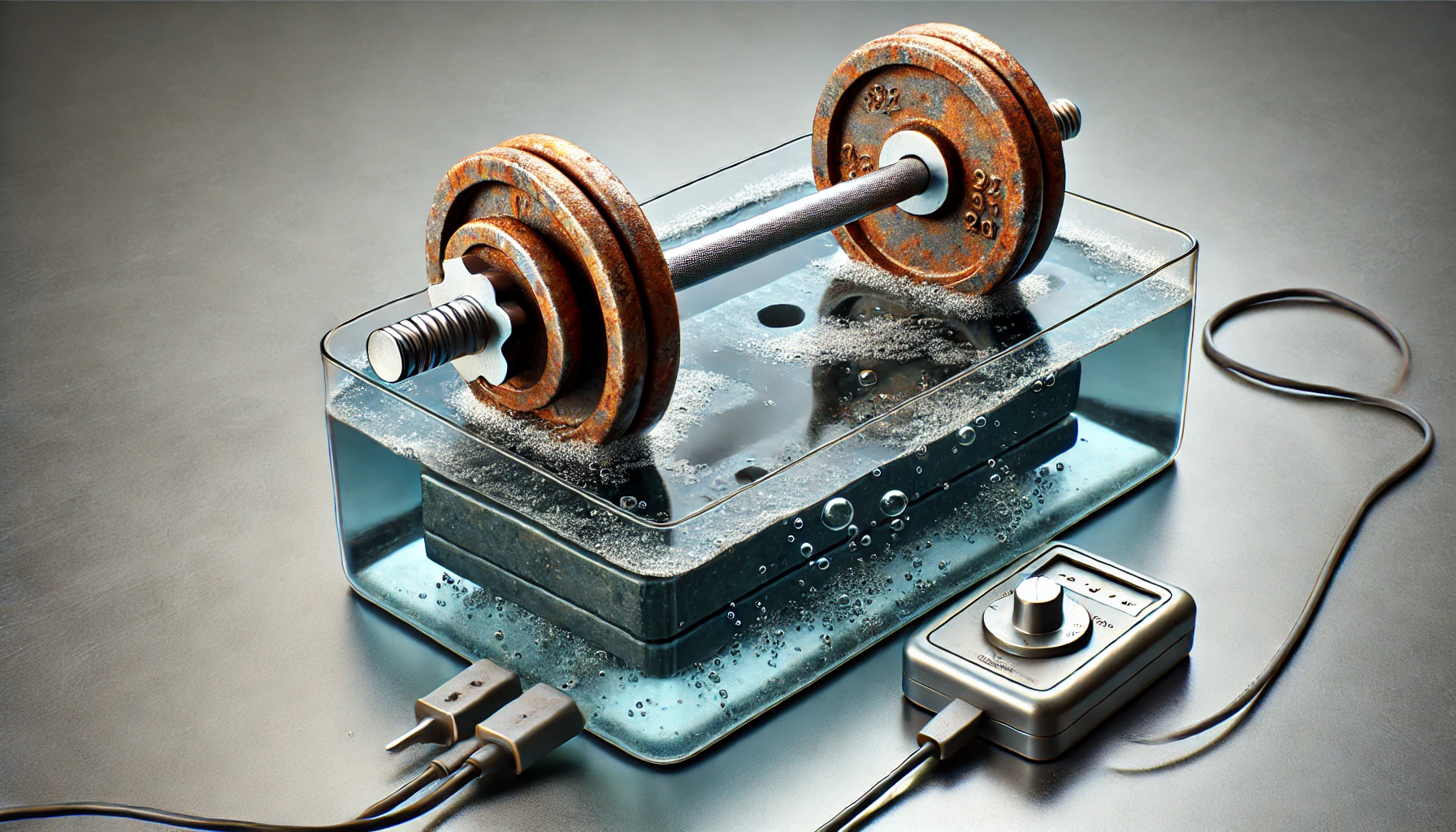

Method 5: Electrolysis – The Advanced Technique

Electrolysis – The Advanced Technique

Electrolysis is a more advanced technique that effectively removes rust without damaging the underlying metal.

Process Explanation: Electrolysis uses an electric current to dissolve rust. The rusty barbell acts as the cathode (negative electrode), while another piece of metal (like a steel plate) serves as the anode (positive electrode). Both are submerged in an electrolyte solution (like baking soda and water). The current pulls the iron oxide (rust) from the barbell and deposits it on the anode.

Necessary Materials: You'll need a power source (a battery charger works well), a container to hold the electrolyte solution, the electrolyte solution itself, the rusty barbell (cathode), and a sacrificial anode.

Setup: Connect the positive terminal of the power source to the anode and the negative terminal to the cathode. Submerge both in the electrolyte solution, ensuring they don't touch.

Advantages & Disadvantages: Electrolysis is very effective, particularly for heavily rusted items, but it requires more specialized equipment and technical knowledge.

Post-Treatment: Protecting Your Barbell

Once the rust is removed, it's crucial to prevent its return.

Thorough Drying: Dry the barbell completely to prevent moisture from triggering further rust formation.

Protective Coating: Apply a protective coating to prevent future rust. Options include oil (WD-40, gun oil) or specialized rust-preventative paint.

When to Seek Professional Help

If the rust damage is severe (extensive pitting, significant weakening of the metal), attempting DIY methods might be futile or even dangerous. In such cases, consider seeking professional help from a metal restoration specialist. They have the expertise and equipment to restore or replace severely damaged barbells.

Conclusion: A Rust-Free Future

Removing rust from your barbell requires careful assessment and the selection of an appropriate method. Simple cleaning is sufficient for light surface rust, while vinegar soaking, baking soda paste, or commercial rust removers can handle moderate rust. Electrolysis is an advanced option for heavily rusted barbells, but professional help may be necessary for extensive damage. Remember, preventing rust through proper storage and regular maintenance is key to keeping your barbell in optimal condition.

Refer to Blog >> How to Choose the Right Weight Plate Storage for Your Gym