Building a Greener Future for Gym Equipment in 2025

Building a Sustainable Future for Gym Equipment in 2025

As a gym owner, distributor, or supplier in the fitness industry, you face growing pressure to reduce the environmental impact of commercial gym equipment—barbells, racks, plates, and machines—while meeting client demands for sustainability. In 2025, carbon footprint management is no longer optional; it's a competitive necessity. Drawing on over two decades of experience in the fitness equipment sector, this guide outlines three innovative practices for outer trade manufacturers to lower carbon emissions through sustainable materials, energy-efficient production, and green logistics. For B-end businesses, these strategies ensure compliance with environmental regulations, satisfy eco-conscious clients, and elevate your brand image in a crowded market.

Explore these expert insights, supported by industry trends and data, to transform your gym equipment supply chain into a greener, more profitable operation in 2025.

Practice 1: Adopt Sustainable Materials for Reduced Emissions

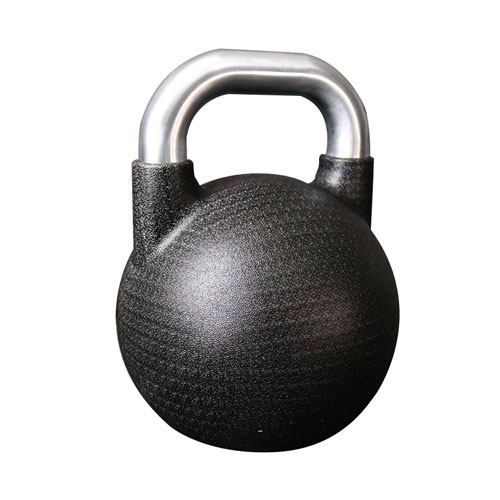

Using sustainable materials is a game-changer for lowering the carbon footprint of gym equipment. Replace traditional steel and plastics with recycled rubber for weight plates, bamboo composites for benches, or low-carbon steel for barbells and racks. A 2024 sustainability report found that recycled rubber plates reduce emissions by 25% compared to virgin materials, while bamboo reduces manufacturing emissions by 15%. For gyms and distributors, this not only cuts your environmental impact but also attracts eco-conscious clients, boosting brand appeal. To implement, source materials certified by standards like ISO 14040, audit suppliers for sustainability, and educate clients on the benefits, enhancing your market position as a green leader.

Learn about durable, eco-friendly options here:

Practice 2: Implement Energy-Efficient Production Processes

Energy-intensive production for gym equipment, such as forging barbells or molding plates, can generate significant carbon emissions. Transition to energy-efficient processes, like solar-powered manufacturing or LED-lit factories, to cut energy use by 30-40%, as per a 2025 industry sustainability study. Use advanced machinery with variable speed drives for steel cutting, reducing energy consumption by 20%. For gyms and distributors, this lowers your supplier's carbon footprint, aligns with green certifications (e.g., LEED), and reduces costs over time, appealing to environmentally conscious clients. Monitor energy audits and invest in renewable energy credits to achieve net-zero production, enhancing your brand's green credibility.

Explore sustainability trends here:

Practice 3: Utilize Green Logistics for Lower Transport Emissions

Transportation accounts for 15-20% of gym equipment's carbon footprint, from factory to warehouse to gym. Adopt green logistics by using electric or hybrid trucks, optimizing shipping routes with AI-driven tools, and consolidating shipments to reduce trips by 25%, according to a 2024 logistics study. Partner with carriers offering carbon offset programs or biofuel options to further cut emissions by 10-15%. For gyms and distributors, this lowers your supply chain's environmental impact, ensures compliance with regulations like the EU's Carbon Border Adjustment Mechanism, and appeals to eco-conscious clients, strengthening your brand as a sustainability leader. Track emissions data and report progress to build trust with stakeholders.

Learn about logistics optimization here:

Achieving a Green Supply Chain for B-End Success

For gyms, distributors, and suppliers, adopting these three innovative practices—sustainable materials, energy-efficient production, and green logistics—transforms your commercial gym equipment supply chain into a model of sustainability. By reducing carbon emissions by 20-40%, you'll comply with 2025 environmental regulations, meet eco-conscious client demands, and elevate your brand image, driving market competitiveness. Industry data shows businesses adopting green practices see a 15-25% increase in client loyalty, while a 2025 sustainability forecast predicts a 10% cost reduction over five years through efficiency gains. With over two decades of fitness equipment expertise, I've seen these strategies position businesses as leaders in a greener future, ensuring long-term profitability and trust.

Stay ahead with green strategies for 2025 here:

Ready to Build a Green Supply Chain for Your Gym Equipment?

Reduce your carbon footprint and enhance your brand with sustainable gym equipment practices in 2025.

Discover how a trusted fitness equipment supplier can help you achieve a green supply chain. Reach out today for expert advice!

FAQ About Carbon Footprint Management for Commercial Gym Equipment

How much can sustainable materials reduce emissions?

Recycled rubber and bamboo can reduce emissions by 25-30%, depending on the material and production process.

What's the cost of energy-efficient production?

Initial investments (e.g., solar panels, efficient machinery) range from $10,000-$50,000, but save 30-40% on energy costs long-term.

How can green logistics lower my carbon footprint?

Using electric trucks, optimized routes, and carbon offsets can cut transport emissions by 15-25% per shipment.

Do green practices increase equipment costs?

Upfront costs may rise 10-20%, but long-term savings and brand value often offset this, boosting ROI.

How do I certify my supply chain as green?

Adopt ISO 14040 certification, conduct emissions audits, and partner with certified suppliers to meet regulatory standards.